In a tape cutter slicer band blades of the same manufacturer with the same pitch and shape are always used. Complete sets are always interchangeable. If very different types of bread are cut, different sets of knives make sense.

FAQ

Frequently asked questions

Filter

for category

Are brochures in other languages available?

Further brochures in other languages are available here. The technical state may not be updated!

- catalogue_i_18_01_1.pdf

- catalogue_poland_17a_rz_120dpi.pdf

- catalogue_r_17d_01_0.pdf

- catalogue_spain_17c_02_0.pdf

- ghd_2017_japan_-_closing_1_0.pdf

- ghd_2017_japan_-_closing_2_0.pdf

- ghd_2017_japan_-_packing_1_0.pdf

- ghd_2017_japan_-_packing_2_0.pdf

- ghd_2017_japan_-_slicer_1_0.pdf

- ghd_2017_japan_-_slicer_2_0.pdf

- autoload_es_17a_02_0.pdf

- autoload_es_17a_02_1.pdf

- bs_20_es_17a_02_0.pdf

- bs_20_i_18a_01_1.pdf

- ec_101_h_es_17a_02_0.pdf

- ec_101_hs_i_18a_01_1.pdf

- ec_101_is_bulgarien_17a_02_0.pdf

- ec_101_is_es_17a_02_0.pdf

- ec_101_ks_es_17a_02_0.pdf

- ec_104_es_17a_02_0.pdf

- ec_104_i_18a_01_1.pdf

- ec_108_i_18a_01_1.pdf

- ec_130_bulgarien_17a_02_0.pdf

- ec_130_es_17a_02_0.pdf

- ec_130_i_18a_01_1.pdf

- ec_130_israel_18a_01_0.pdf

- ec_135_i_18a_01_1.pdf

- ec_140_s_i_18a_01_1.pdf

- ec_150_v_es_17a_02_0.pdf

- ec_150_v_i_18a_01_1.pdf

- gbk_220_bulgarien_17a_02_0.pdf

- gbk_220_es_17a_02_0.pdf

- gbk_220_i_18a_01_0.pdf

- gbk_420_bulgarien_17a_02_0.pdf

- gbk_420_es_17a_02_0.pdf

- gbk_420_i_18a_01_0.pdf

- gs_60_es_17a_02_0.pdf

- gs_60_i_18a_01_0.pdf

- hb1_hb2_es_17a_02_0.pdf

- hs_es_17a_02_0.pdf

- hs_i_18a_01_0.pdf

- km_600_p_i_18a_01_0.pdf

- lv_i_18a_01_0.pdf

- pp_30_es_17a_02_0.pdf

- pp_30_i_18a_01_0.pdf

- sl_20_bulgarien_17a_02_0.pdf

- sl_20_es_17a_02_0.pdf

- sl_20_i_18a_01_2.pdf

- sl_25_bulgarien_17a_02_0.pdf

- sl_25_es_17a_02_0.pdf

- sl_25_i_18a_01_0.pdf

- sl_30_bulgarien_17a_02_0.pdf

- sl_30_es_17a_02_0.pdf

- sl_30_i_18a_01_0.pdf

- sl_50_es_17a_02_0.pdf

- sl_50_i_18a_01_0.pdf

- stv_30_es_17a_02_0.pdf

- stv_40_es_17a_02_0.pdf

- vs_320_sv_es_17a_02_0.pdf

- vs_320_sv_i_18a_01_0.pdf

- vs_320_es_17a_02_0.pdf

- vs_320_i_18a_01_1.pdf

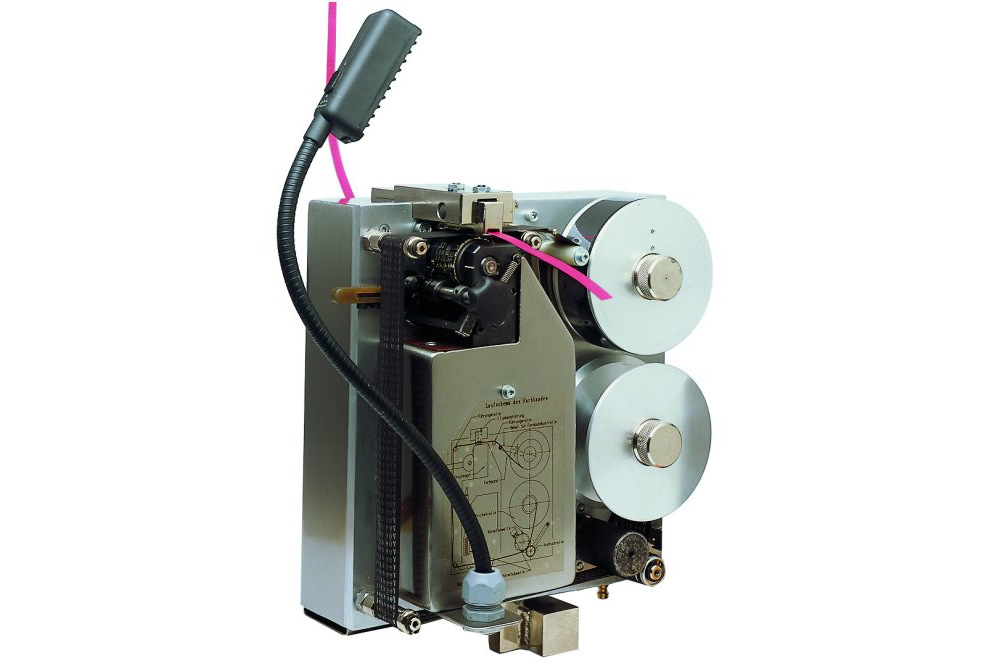

Does GHD Hartmann supply its own printer devices?

GHD Hartmann supplies HPD printers with a choice of between 6 and a maximum of 13 positions for printing clip tape. A 6-digit HPD printer can be offered for closures such as Kwik-Lok® or Schutte Clipps®.

How is the blade change performed on a band slicer?

The slicer band blades are a wearing part of the band slicer. The service life of the slicer band blades varies depending on the type of bread. Usually a complete set of slicer band blades is always changed, as the slicer band blades stretch slightly during use and thus become "longer".

For the slicer band blades change you can disassemble the knife guide for easy accessibility quickly and easily. Depending on the experience, changing a knife set takes about 5-10 minutes

How can I determine the size of bags?

Bag sizes depend on the products and the orientation of the products in the bag.

In any case, the product tolerances must be considered. This is especially important when several products are packed side by side, one after the other or one above the other in a single package. A beautiful packaging fits as closely as possible to the product and supports the product. The sizes recommended by GHD Hartmann can be looked up in an Excel spreadsheet.

Which controls can GHD Hartmann Maschinenbau offer?

In addition to contactor controls for simple devices, GHD Hartmann Maschinenbau offers systems from the manufacturer Omron as a standard controller for more complex tasks.

Siemens or Allen Bradley are available as options.

How loud is a machine by GHD Hartmann?

The noise emission initially depends on the type of machine. Packaging machines, cutters or systems for grouping are fundamentally different due to the different functions.

Another factor is the nature of the products, which can behave differently during processing and transportation. A machine may be very quiet at idle, but produces varying amounts of noise during processing, depending on the products.

The type of cover also has a great influence on the noise emission: Polycarbonate viewing covers significantly reduce the noise level, while perforated grids can not significantly reduce noise emissions.

As a rule, the maximum noise emission of the machines is not more than 78 dB (A).

What compressed air quality is recommended for machine use in the food industry?

According to ISO 8573-1 with reference to VDMA standard sheet 15390-2, we specify a compressed air quality that we recommend when using the machines and devices.

What is the difference between packaging and sealing?

Packaging means: positioning products automatically in a bag, extracting residual air from the bag, closing the bag close to the product inside the packaging machine.

Closing means: The products are either introduced externally into the bag or manually inserted into the bag on the device.

Some devices suck the residual air out of the bag, after which the bag automatically closes inside the device.

What is the difference between a fixed blade guide and an adjustable blade guide?

Adjustable blade guides:

Negative:

- Complicated access for cleaning

- Complicated exchange of guiding pads

- One position for wearing of pads

- Correct cleaning would require the dismantling of the both adjustable guides. This requires hours

- Not according to sanitary demands (local laws and rules)

- If used in combination with oil the unit might “stick together”

Positive:

- One system for every slice thickness (if within the adjustable range)

- Tolerances within the length of loaves are divided to the slice thicknesses

Exchangeable blade guides

Negative:

- One set of blade guides per slice thickness required

Positive:

- Always correct adjustment of slice thickness

- Fingers could be turned several times in case of wearing

- Fingers could be easily exchanged in case of wearing

- Jet-wash cleaning and drying outside the packaging area

- Good access for cleaning

- Good access for blade exchange

- Better visibility of the slicing process

What is the difference between a type GBK and type VS ?

In the case of the GBK type, standing bread slices are packed, while the VS type packs lying stapled slices. Both systems are able to package other types of products and products grouped differently.

GBK type

- Upright standing bread slices

- Whole breads

- Grouped products - fast food

VS type

- lying stapled bread slices

- Stacked flat breads (tortilla, arabic bread, pitta)

- Grouped products

What is a quality seal?

By "quality closure" is meant the single or double row perforation sealing of the bag ruffle. The bag can not be opened without breaking the seal.

Customers can thus control possible manipulations of the packaging or the products on the shop shelf.

The quality seal is not a hermetic seal.

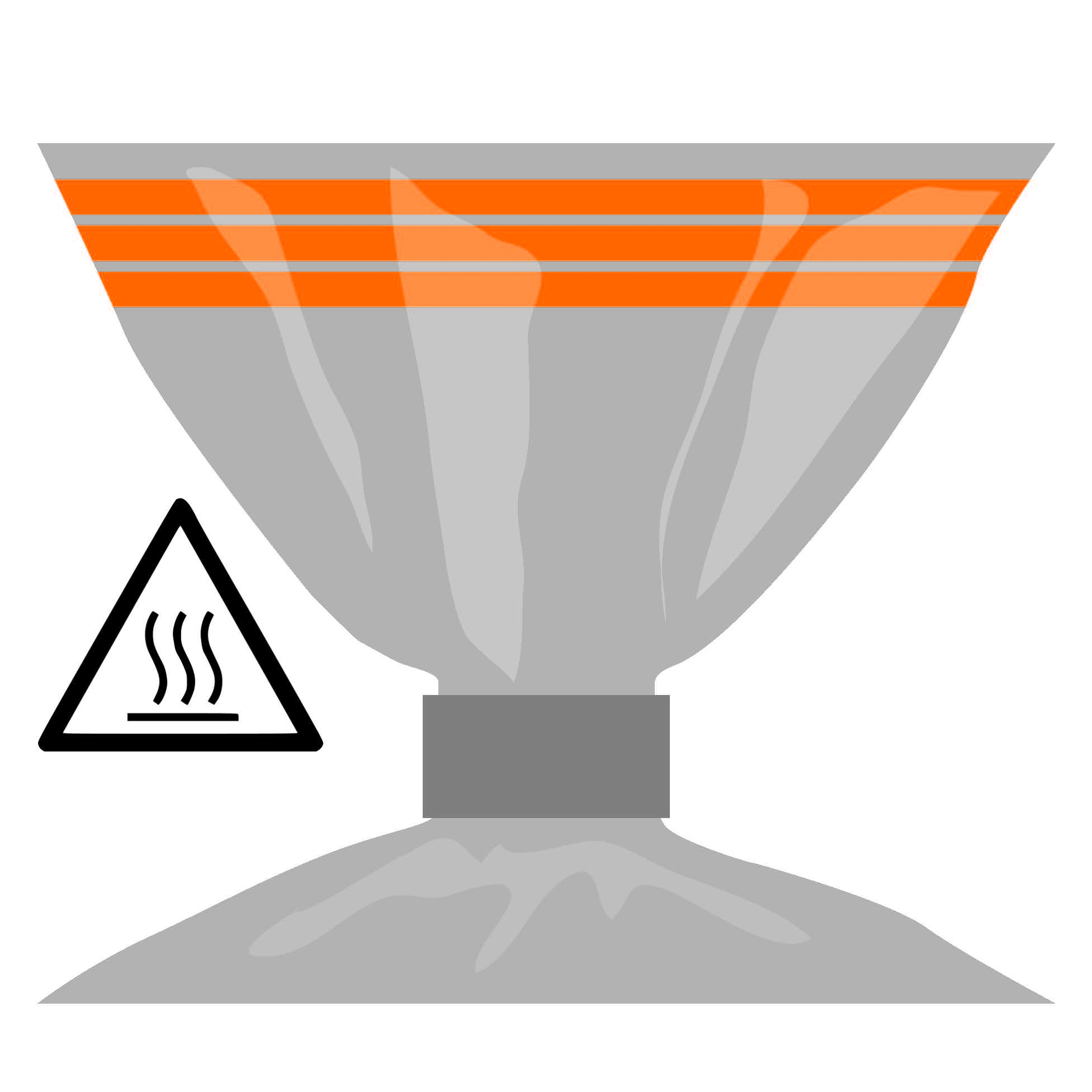

What should be considered when using a density scanner?

When using X-ray inspection systems, user-specific laws and regulations must be observed by the user. To operate the plant within the EU, the operator of the facility must be trained as a radiation protection officer. The radiation protection approval (TÜV approval) should take place during commissioning.

A radiation protection inspection can only be commissioned by the operator of the facility. A decrease can be accompanied by WIPOTEC-OCS GmbH or GHD Hartmann.

Which bag closures can be used with packaging machines or sealing devices from GHD Hartmann?

Hartmann machines process a large number of different closures. The capping system can be supplied by machine type and series for a specific type of bag closure.

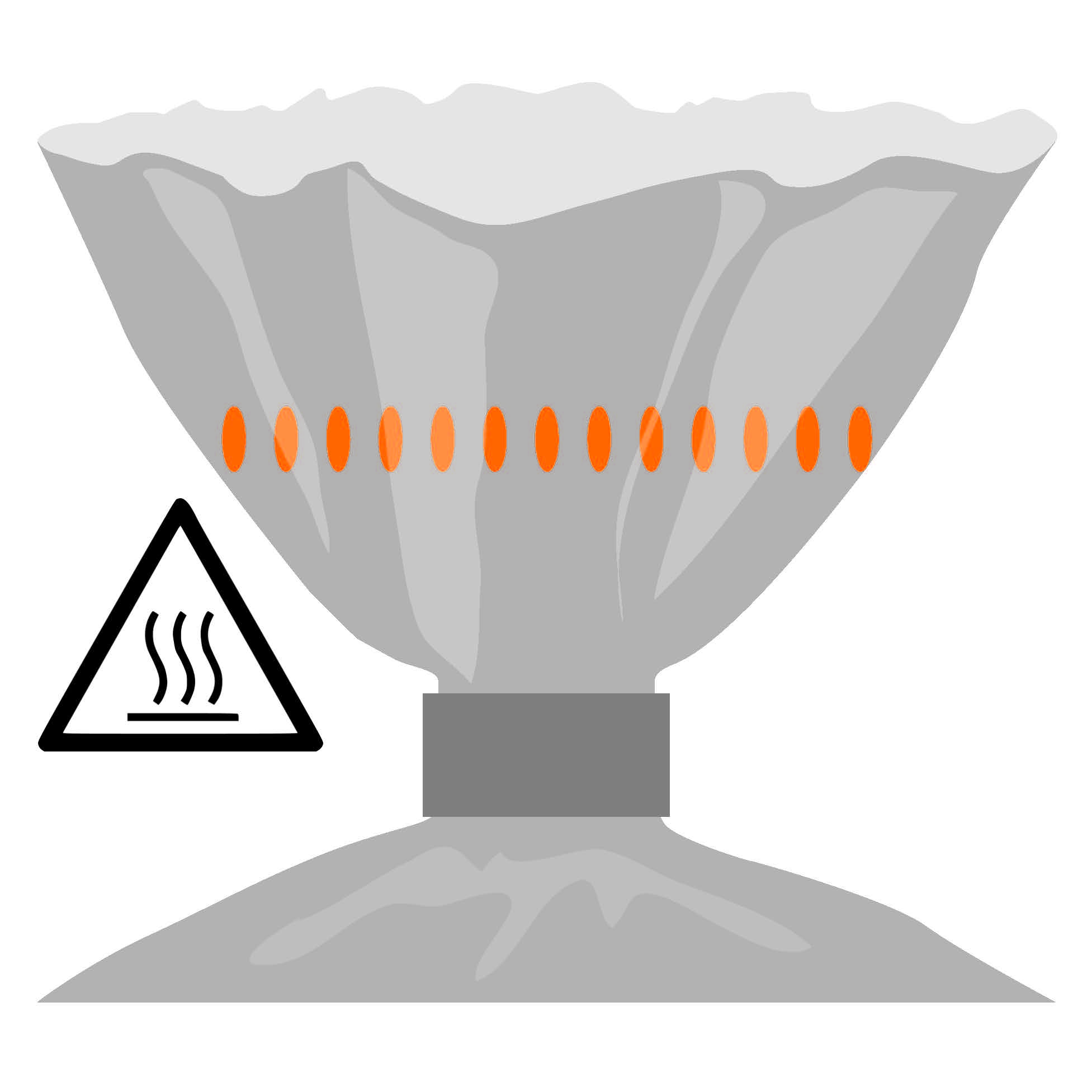

Can the machine be cleaned wet?

The machines are designed according to protection class IP54. Wet cleaning of the machines inside the cutting and packaging room is not recommended as moisture and bread crumbs directly cause the formation of mold spores.

Wet cleaning should therefore only take place outside the cutting and packaging room: components of the machine, such as guide plates, can be dismantled and cleaned at an external washing area. After drying and disinfection, the hygienically flawless dry components can be inserted into the device and reused.

Change kits allow cleaning and preparation in addition to the production operation.

Is it possible to combine a GHD Hartmann Schneider with other packaging machines?

Of course, our bread slicers can not only be combined with capping and packaging machines from GHD Hartmann, but also with machines from other manufacturers.

Take advantage of our many years of experience for optimum coordination and connection.

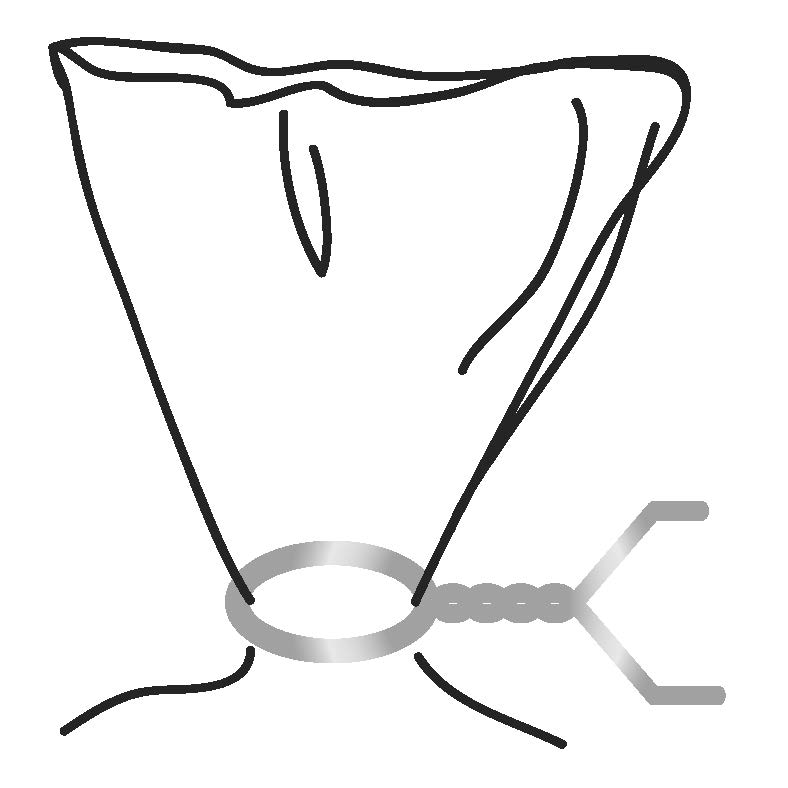

Which bag closures can GHD Hartmann offer?

Hartmann closing devices and Hartmann packaging machines have an integrated aggregate for the closure application. Depending on the machine type and series, the closing system can be supplied for the application of a certain type of bag closure. Later conversions are partly possible.

Clip closure: The closure used very often in Europe. Cost effective with the possibility of printing on the closure. Good to use for PE bags, PP bags and paper bags.

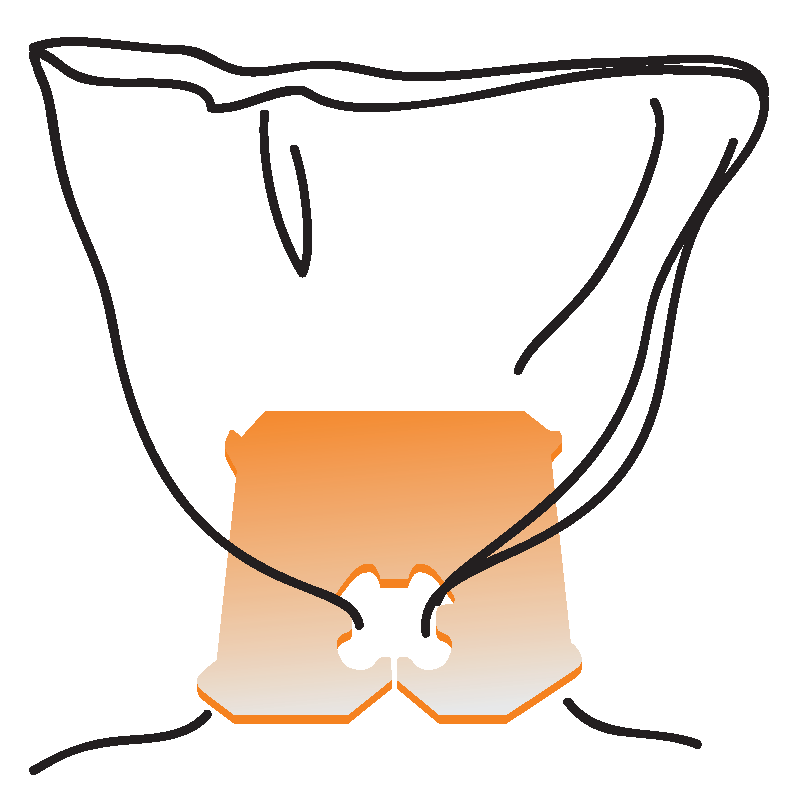

Kwik-Lok ®; Schutte Clipps ® G or corresponding closures: Widespread in North America and Asia. No metal components in the closure, but difficult to detect or undetectable. Unsuitable for paper bags. A printing of the closure is possible.

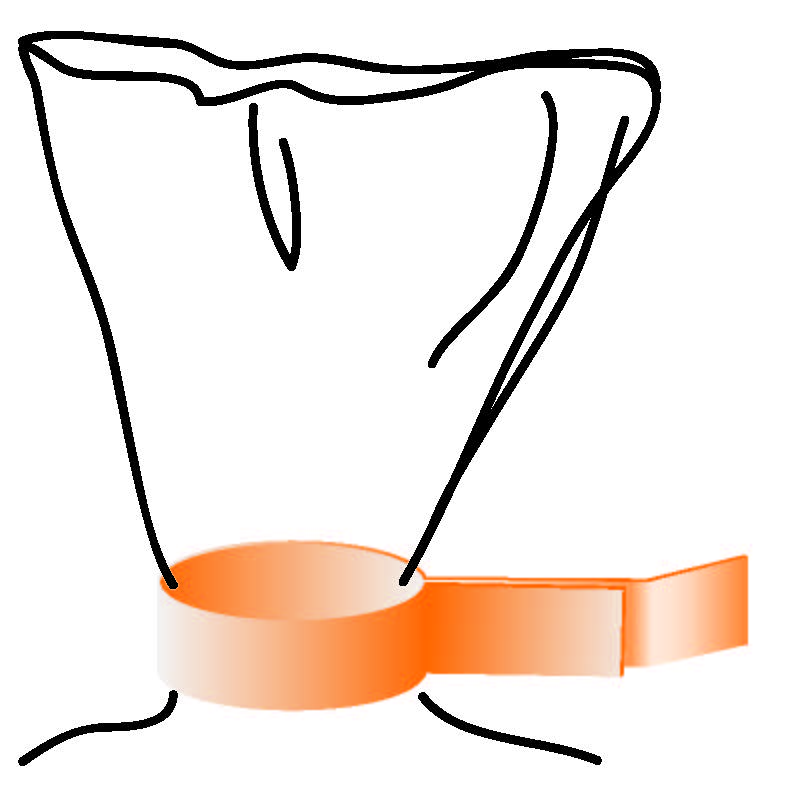

Tape - Closure: In the United Kingdom, in English-speaking countries and occasionally in Africa, the tape closure is applied. Hartmann offers this type of closure in packaging machines and specially designed sealing devices. A printing of the tape closure is possible.

Sealing: The sealing of bags with a sealing system is available for various types of machines. For closing, the filled bags can be sealed, or the frill can be sealed in addition to the conventional closure. The packaging material and its welding properties must be observed.

In the case of pillow packs, the packaging film is sealed on the longitudinal and transverse side and, optionally, as a division in the longitudinal direction. Depending on the machine type, the protruding film is cut off during sealing.

Tamper proof / Quality closure: In addition to the clip closure or Kwik-Lok ® / Schutte Clipps ® G closure, a tamper proof application system can optionally be installed within the GHD Hartmann machine. This lock is either one or two rows and can be activated. It increases security against manipulation from outside during sales.

Warp Close: With the Wrap Close, paper but also plastic bags can be closed. The bag is automatically wrapped on the opening side and secured and closed with a label.

Twist - Closure: This closure is known in South America and in English-speaking countries. GHD Hartmann cannot offer integration within the packaging machines. This closure is attached with a separate device provided by the customer after the products have been packed in the bag. For technical reasons, it is not possible to remove air from the bags when they are closed.