Machine history

Machines for bakery production

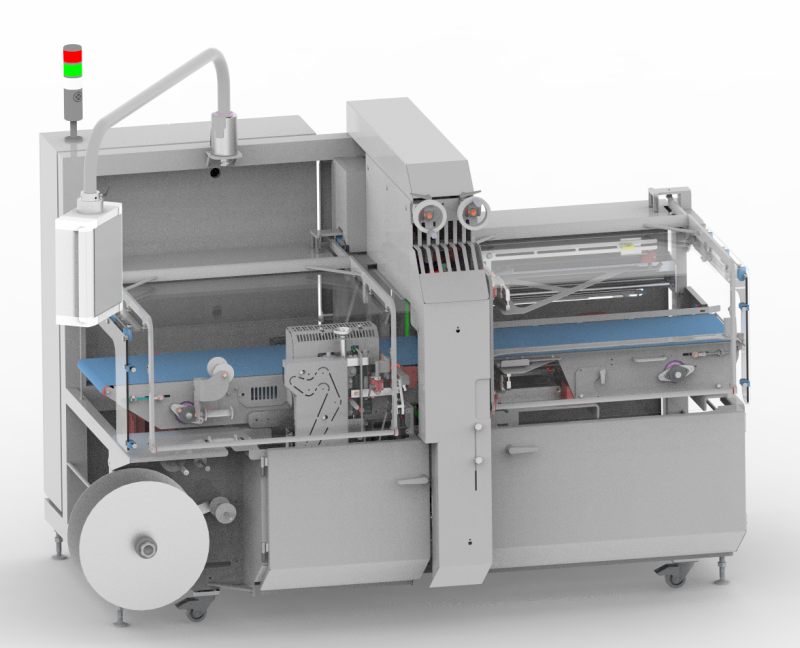

Machine for wrapping and sealing products with foil as transport and storage packaging

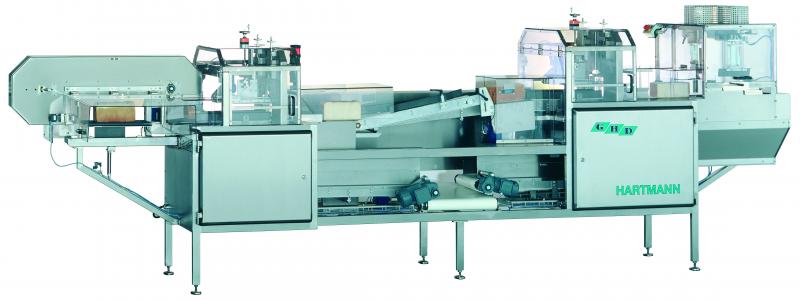

Automatic packing and closing of bags with a "WrapClose" wrap closure and label sticker application inside the machine.

Modification of the closing machine EC 101 H, but equipped with a closing unit for tape (Thurne).

For multi-lane slicing of products, the machine types XL and XXL are available for working widths of up to 550 mm and 750 mm. Especially South American sweet pastries can be processed excellently with these tailors with great performances.

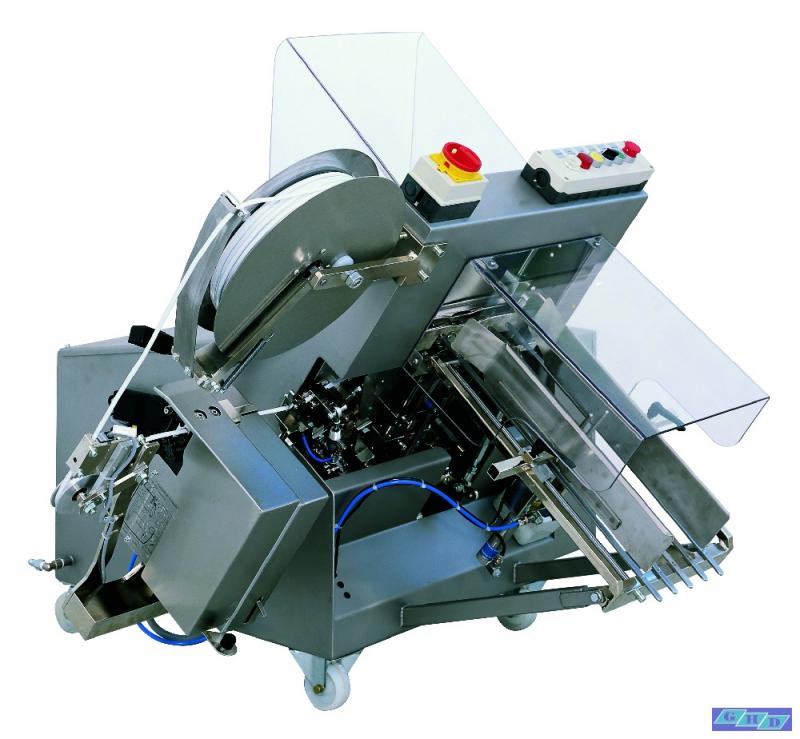

Special system with an integrated sealing and closing system. Open bags are sealed, the bag frill is folded in motion and completed with an additional closure such as Kwik-Lok® or Schutte Clipps®. The device creates the "Hartmann umbrella look", which is particularly popular in Asia.

Machine for single or multi-lane stacking of flatbread or Lebanese bread.

For separating and aligning hamburgers, hot dogs, bread rolls or similar products. Feed with a disordered product stream. Depending on the capacity requirement, versions as a single to quadruple system are possible.

Machine for multi-lane simultaneous stacking of small, flat products.

Modification of the closing device EC 101 with an integrated sealing system instead of a system for applying clip closures or other closures. Different types are offered with or without inclination of the product table.

Extension of the slicer program with a reciprocate slicer for sugary products that can not be processed by means of a band slicer.

Machine with three-line infeed and turning cassettes for significantly higher performance, based on the STV 50.

Shortened version of the classic VS 320 for small product stacks. The shortened version allows higher cycle speeds.

Disc slicer for simultaneous multi-lane slicing of burgers, hotdogs and similar products.

Band slicer Selectra SL 30 with wide drum design for the integration of an adjustable blade guide. This design allows a much larger adjustment range for the disc thickness.

The first system that enables the industrial-scale slicing of baguette through a combination of X-ray scanner, circular knife slicer and portioning machine. Further components of the line later receive independent designations. The plant will later receive an IBA Award.

In addition to the EC 101 HS, the versions EC 101 IS and EC 101 KS are also available as short versions “S” of the original machines.

Small version of the EC 101 H for tight spaces.

Machine for separating small bakery goods. Classic use for unloading baking trays with burgers or bread rolls. Usually in conjunction with subsequent (partial) manual work steps.

Simple vertical slicer for splitting products.

The one to ten-lane device (ST 1 to ST 10) automatically separates the sliced loaves.

This machine is an elementary part of an independent plant for slicing and portioning long bread bars up to 3 m in length.

As an installation unit in foreign packaging machines for attaching an additional clip closure.

Machine for small flat products. The machine stacks and rotates the two-lane stack by 90 ° for optimized grouping prior to packaging.

The band slicer Selectra SL 25 is the performance class between the SL 20 and SL 30 slicers. It fits perfectly with the GBK 220 or VS 320 packaging machine.

The packaging machine VS 320 SV 12 T is a special development for the packaging of tortilla bags. The bag bottom is welded. Drives with servo motors. At first 12 “diameter, later also an additional version with product diameters up to 14”.

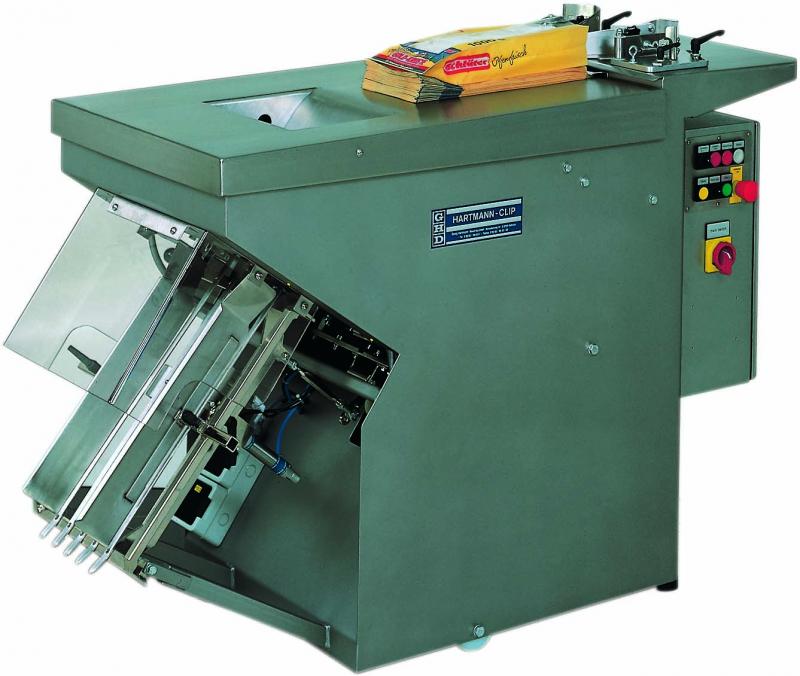

Machine for manual filling of bags with automatic closing.

To increase the performance of two-lane disc slicers. Versions with several slicing stations for wedge cutting or double butterfly cutting are also offered.

Presentation of the Slectra SL 60 tailor in high-end industrial equipment.

Peeling machine for removing the bread crust of toasted bread.

Starting in 2005, various systems will be developed and sold to address the diverse grouping needs and packaging needs. Basically, depending on the packing scheme, there are systems in line or in a 90 ° arrangement of the machines. In addition to the possibility to load one or two layers, there are possibilities for turning the products during loading.

In line with customer requests, Hartmann will increasingly offer line distribution systems for the automatic distribution and feeding of products from 2004 onwards. These systems control the product flow to the individual slicing and packaging lines. In addition to the SLVS control system, a line distribution system also includes customer-specific transport conveyors, line distributors and product-specific separation systems.

First stand-alone version of a grouping line and feeder type AL 50 for burger rolls in combination with a packaging machine GBK 420.

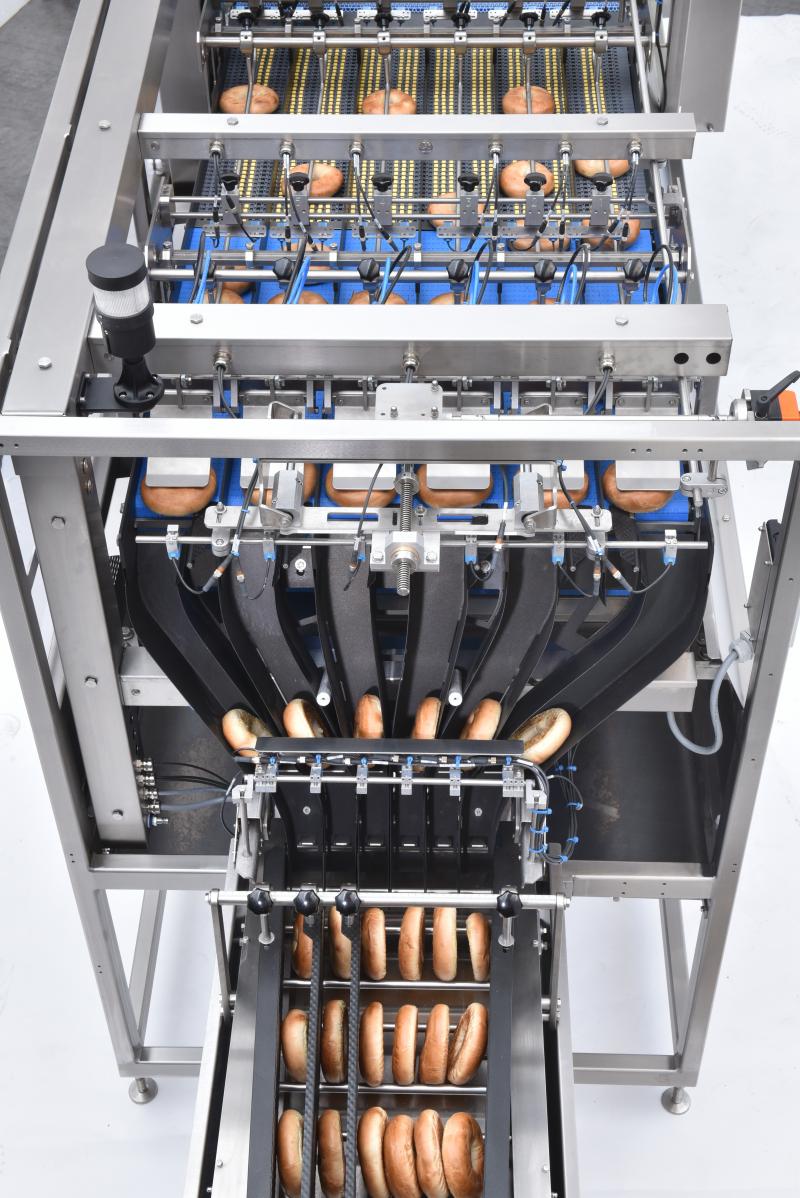

Originally intended for the North American market, but used worldwide to group bagel products.

Broader version of the Selectra SL 28 for products up to 550 mm.

The closing machine EC 155 is used to close large-volume, vertically filled bags.

The Selectra SL 28 cutting machine has been specially developed for southern European requirements and product specifications.

Broadening of the Selectra SL 30 to product widths (bread lengths) up to 550 mm.

Broadening of the Selectra SL 30 to product widths (bread lengths) up to 650 mm.

The tray loader KP 30 is the supplement to the automatic pillow packaging machine: Packaged products are loaded in line in supplied trays.

The first machine for packaging hamburger rolls and hotdog rolls in pillow packaging will be designed, built and later delivered this year. Many details characterize the following machines of this series.

System for vertical filling with bulk goods. Automatic bag feed and integrated closing unit make the machine very compact.

Packaging machine GBK430 with various technical differences and higher equipment than the packaging machine GBK 420

Machine for the horizontal cut of bread rolls, hot dogs, bagels and similar products. Version HB 1 with single cut, version HB 2 with optional double cut.

The slicer Selectra SL 20 serves the small and medium-sized bakeries with a simplified equipment.

Special variant especially for use in small shop-bakeries.

Automatic packaging machine GBK420 with significantly increased cycle performance.

Closing machine for products on trays and oblong product formats.

Band slicer Selectra SL 30 for industrial production. Due to the solid construction, this machine type has become the backbone of many systems and developments and has already been delivered a hundredfold.

The packaging machine VS 320 is the basic machine of further types for the packaging of stacks of horizontal orientated products.

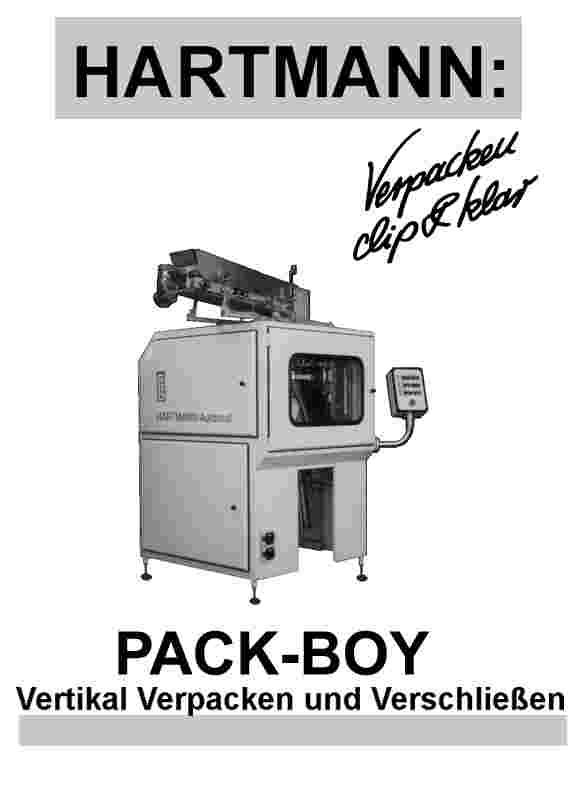

Machine for packing sliced and uncut breads with upright standing slices. Application also for packaging of grouped products.

First band slicer by GHD Hartmann for upright standing bread slices.

First version of the machine for slicing hotdog, burger rolls, sandwich or similar products.

Packaging machine GBK 205 for smaller capacities and tight space.

Servo-driven closing machine for bulk goods with capacities of up to 100 cycles / min

"Quickly packaged in double stroke" - the first packaging machine with 2 alternately working slide arms.

Closing machine for vertically filled bags.

The EC 135 closing machine is an ideal complement to attach a closure underneath a vertical bagger.

Revolving table for intermediate buffering and hand removal of ready closed bags.

Extension of the packaging machine GBK 210 with a one-stroke. For the first time both whole and standing slices can be packed.

Closing machine EC 150 V4 for closing tubular bags with bulk material.

Bag filling and closing machine EC 101 K with fixed closing unit and drive-dependent cycle power.

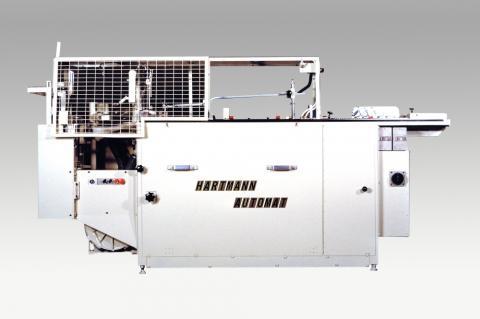

Automatic packaging machine VS 310 for horizontal discs. There were different variants of this type.

Bag filling and sealing machine EC 101 I with intermittent operation of the closing machine.

Closing machine EC 140 for manual filling with automatic closing system

The closing machine EC 130 is a small, universally applicable machine for a variety of uses.

The packaging machine GBK 210 for packing sliced and uncut breads with upright standing bread slices.

First packaging machine for whole breads

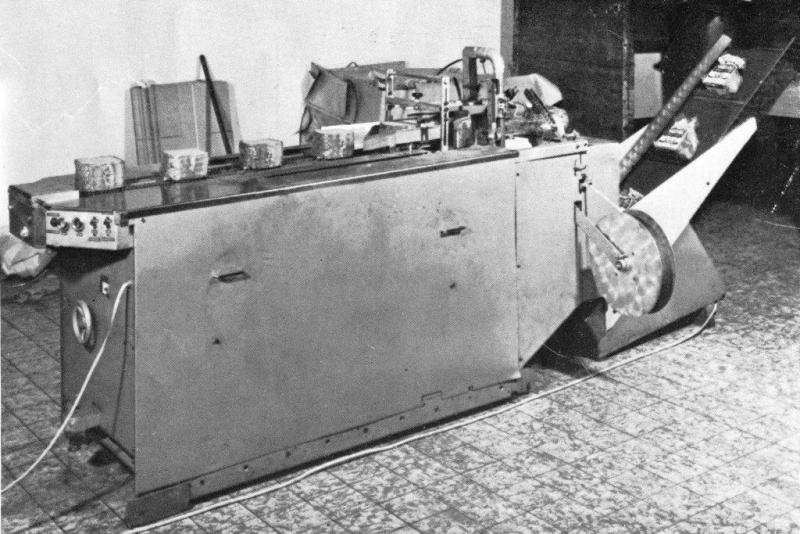

Prototype of the first packaging machine