GBK 220

Packaging machine - GBK 220

Pictures

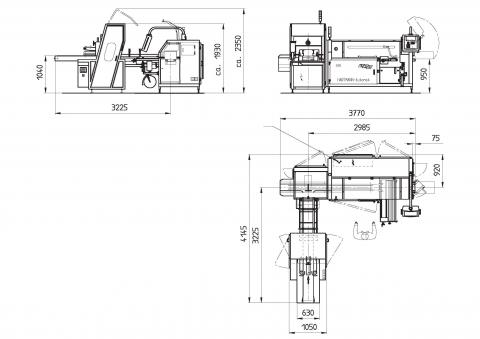

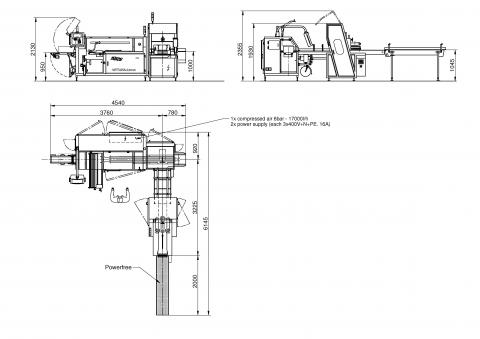

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, lacquered in stainless steel design colour, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Footrests without dowel holes |

| Conveyor system with adjustable speed |

| Transfer line with pusher dogs, base plate made from plain stainless steel |

| Lateral guides, plain stainless steel |

| Lateral guides above transfer line, manually adjustable by handwheel |

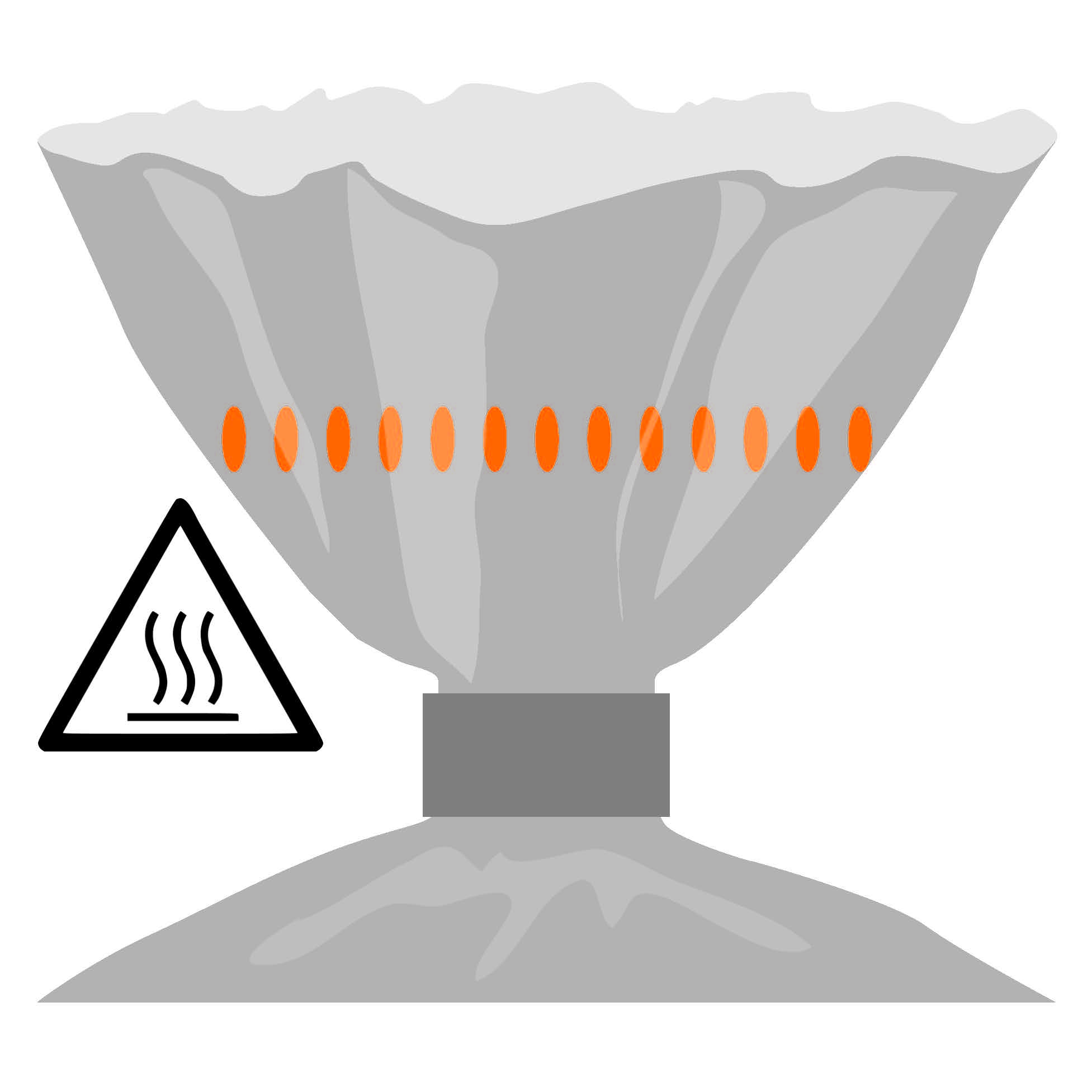

| Bag aspiration through product pusher head |

| Integrated side channel blower device |

| Product pusher and bag air aspiration |

| Single bag lifting device |

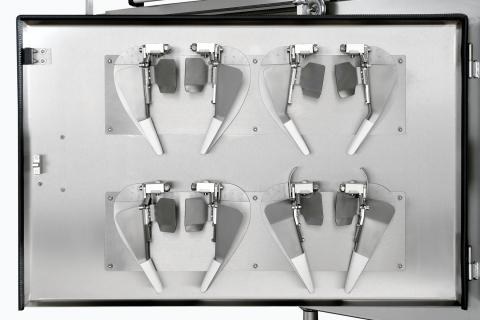

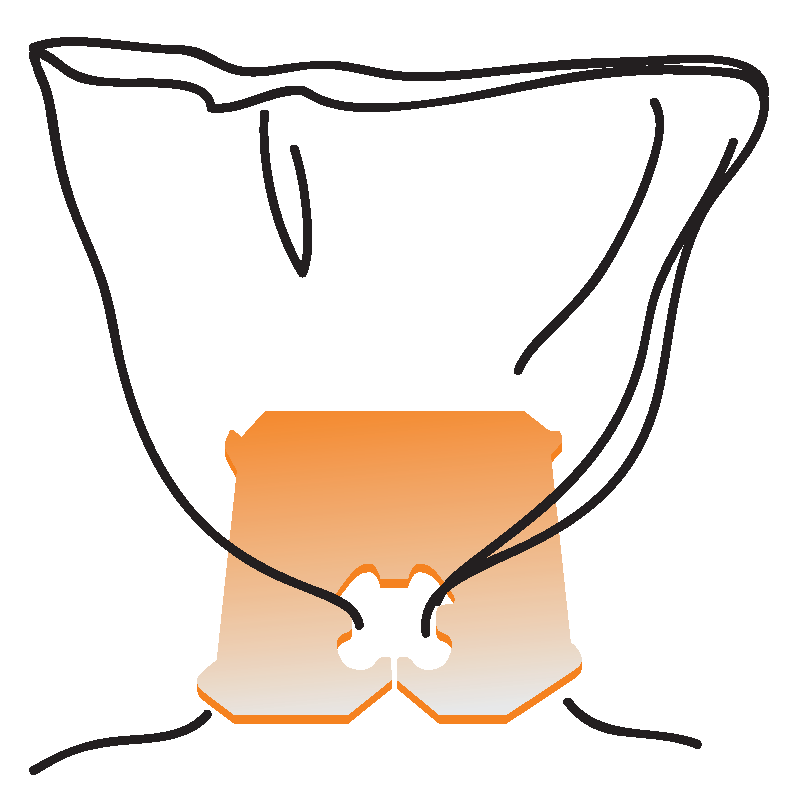

| 1st set of spreading plates for bag opening |

| 2nd set of spreading plates for bag opening |

| Automatic bag magazine `ABM-70 Twin` for straight U-shaped brackets and cropped U-shaped brackets |

| Automatic infeed and positioning of the next batch of bags |

| Automatic controlled switch-off at empty bag magazine |

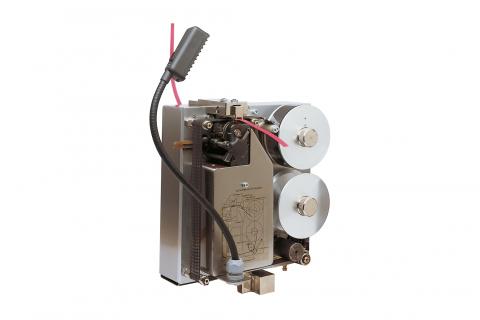

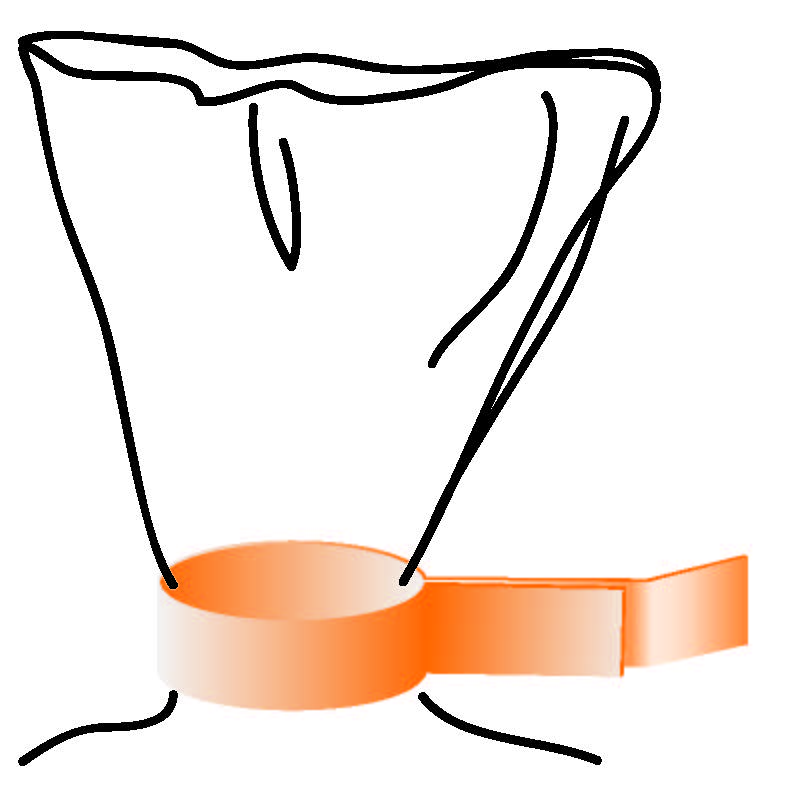

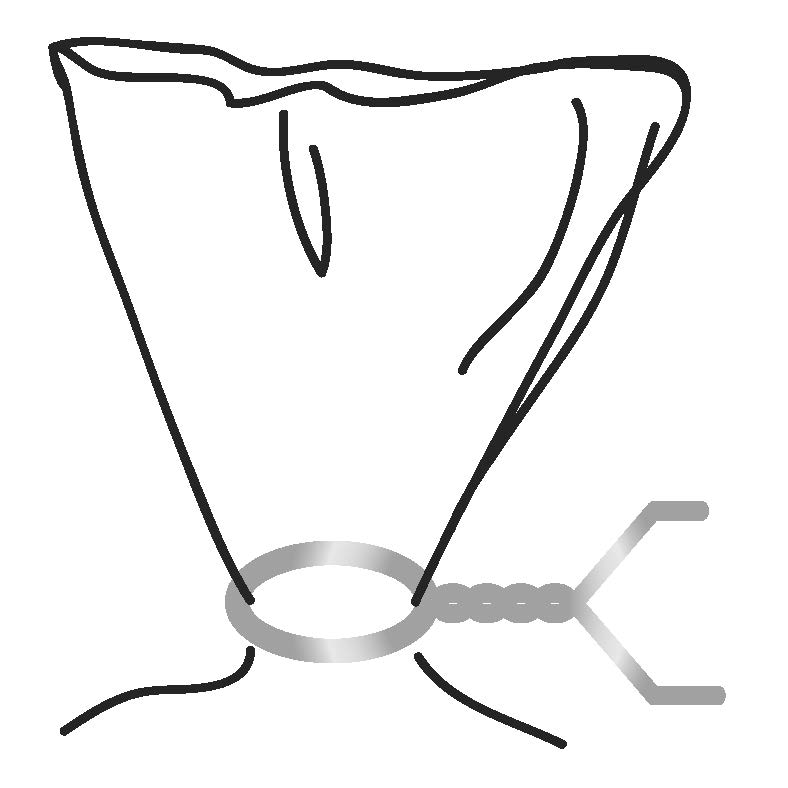

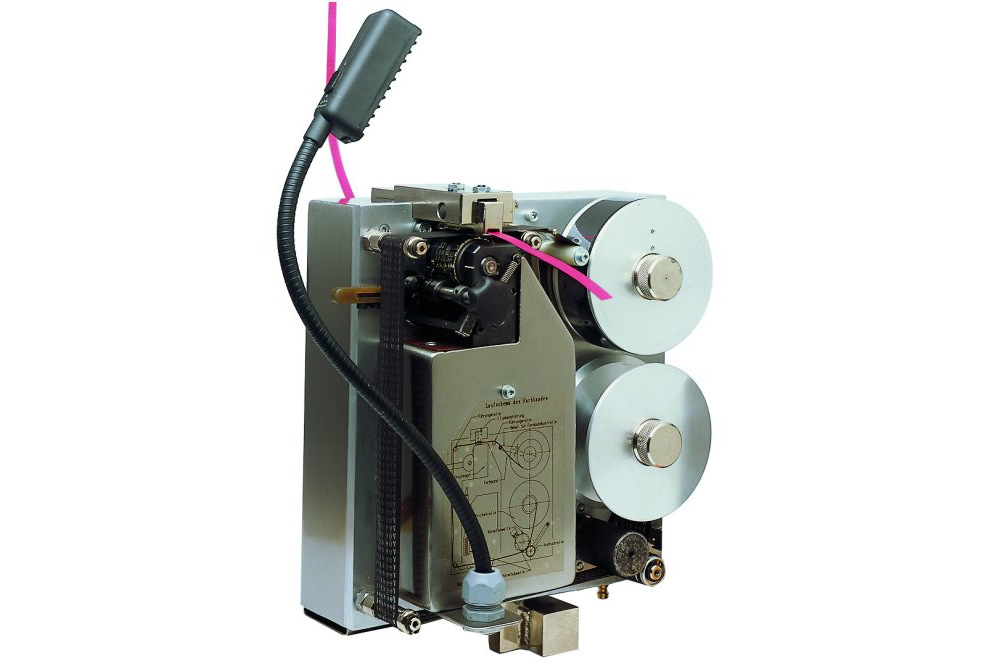

| Closing aggregate for clip |

| Single spool for closure rolls |

| Powered Discharge Conveyor |

| Product outfeed with lateral guides, manually adjustable |

| Sterile filter for sterilization the compressed air coming into contact with the products |

| Signal lamp - red / green |

| Signal horn |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Comfort-operating panel, rotatable with support arm system |

| Controls + touchpanel Omron |

| Frequency converter Hitachi |

| Automatic Stand-By in case of missing products |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| п»ї |

|---|

| Welded machine frame, stainless steel, standard (crank-rockers made of galvanized steel) |

| Protection hoods made of perforated stainless steel panels |

| Crosswise infeed for Bagels , Muffins |

| Crosswise infeed, 1 infeed paddle for upright slices |

| Crosswise infeed, 2 infeed paddles for upright slices, for half bread loaves |

| Extension (915 mm) for inline infeed. Additional space for manually infeed |

| Transfer line made from a roller carpet with changeable carrier plates |

| Side guides, smooth VA with blowing nozzles for product stabilization |

| Integrated self-cleaning vacuum filter (Jet-filter) with side channel blower device |

| Bag magazine type `HBM-70` - semi-automatic for straight and cropped U-shaped brackets |

| Extended bag magazine for 5 bundles |

| Illumination of the working area inside the machine |

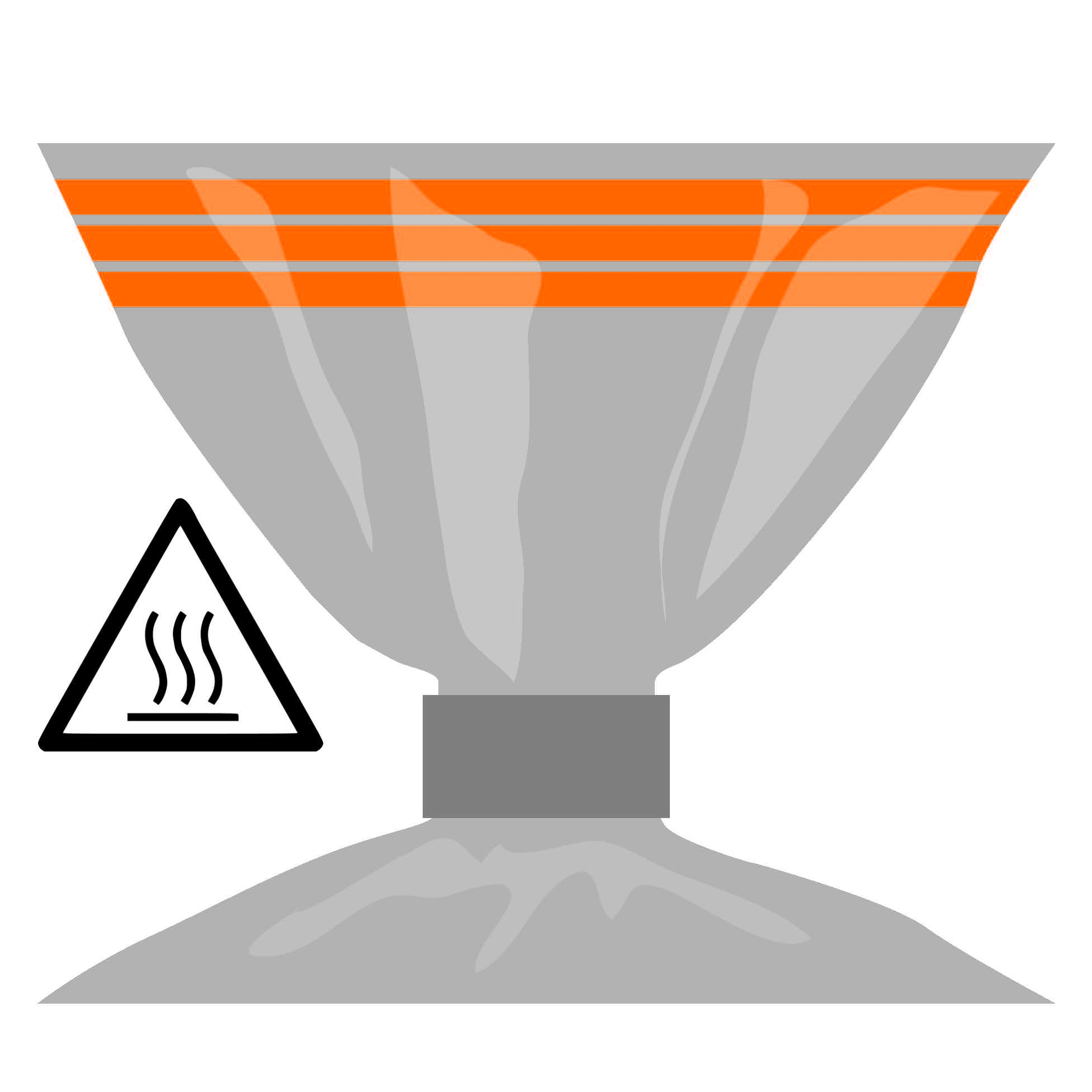

| Tamper proof sealing - Perforating and sealing the frill of the closed plastic bag with a heated comb - 1 row (only in combination with clip-closure or Kwik-Lok В® closure) |

| Double spool for closure rolls |

| HPD-Printing on the clip, 6-digit |

| HPD-Printing on the clip, 9-digit |

| HPD-Printing on the clip, 13-digit |

| Preparation for retrofitting an HPD printer (without printer, printer assembly or commissioning) |

| Closing unit for KLR – closures, endless belt with driven feeding and cutting knife |

| Closing unit for closures Kwik-LokВ® type J-NRP, Schutte Clipps G or equivalent |

| HPD printer, 6 digits for Kwik-LokВ®, Schutte Clipps G or equivalent |

| Closing unit for inline tape |

| Sealing aggregate, pulsed heating of sealing wires - PE-foils (max. 35-40 cycles/min) |

| Sealing aggregate, permanent heated sealing plates, non-stick coated - PP-foils (max. 35-40 cycles/min) |

| In line outfeed with slide type `storage table` |

| Product control on discharge conveyor and press jaw, adjustable by hand wheel |

| In line discharge: Accelerator belt, length 750 mm, foldaway, fixed at machine door |

| Switch cabinet with service interface FrontComВ® with LAN and power socket |

| Additional signal lamp |

| Switch cabinet with air-conditioning |

| RFID - Panel access authorization per chip, 10 pieces with up to 5 authorization levels |

| RFID - Additional chip, 10 pcs. with up to 5 authorization levels |

| Frequency converter Allen Bradley |

| Remote service, VPN-Switch INSYS, (Master unit) |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

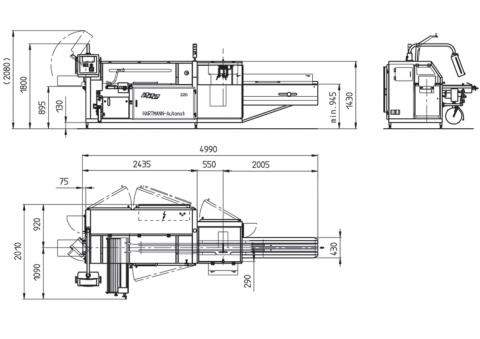

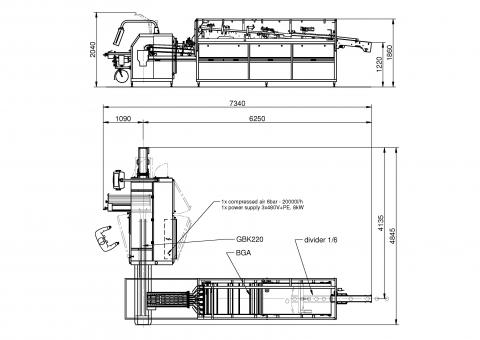

GBK 220

The GBK 220 packaging machine is ideal for whole and sliced bread (standing slices, toast bread, etc.). The principle of the vacuum slider developed by HARTMANN has optimally proven itself in practice. The sophisticated technology of these machines guarantees optimum packaging, venting and closing. The packages are closed with the proven closing unit, which is characterised by its reliability and long service life. By consistently separating the product work area from the mechanical drive, this generation of machines also meets cleanroom requirements.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 4500 mm, Width: ca. 2010 mm, Working height: min. 960 mm, Height: min. 2080 mm |

| Weight: | 1700 kg |

| Product dimensions: | Length: 100 - 400 mm, Width: up to 260 mm, Height: 30 - 170 mm (other dimensions on request) |

| Capacity: | 1800 - 2700 packages /h |

| Speed: | adjustable |

| Controller: | Omron |

| Operating panel: | Touchscreen |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | 4 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Packing material: | pre-manufactured plastic bags, or paper bags (paper with clip closure only) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |