SW 40

L- Sealing unit - SW 40

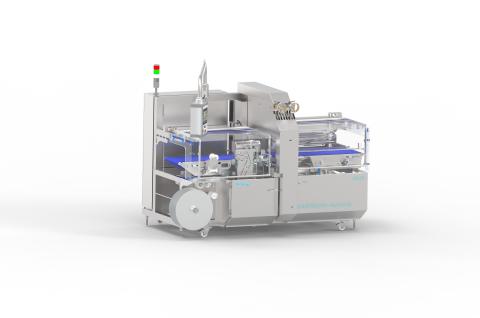

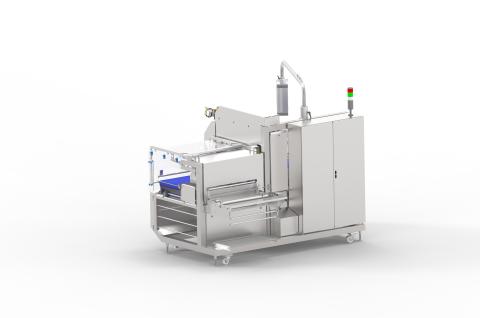

Pictures

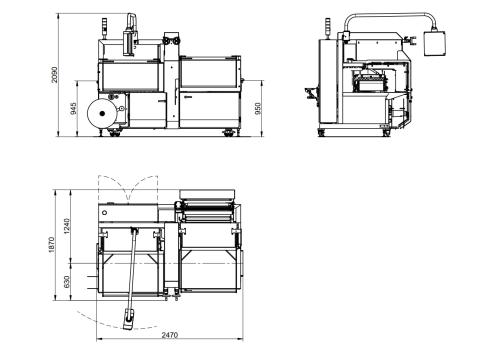

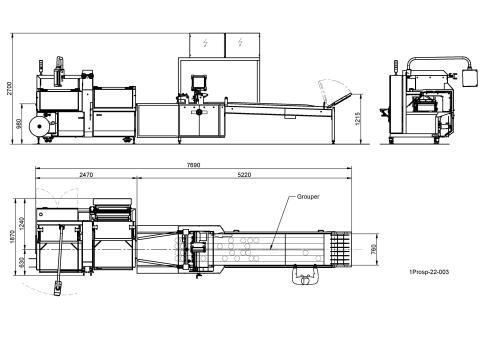

Drawings

Standards

| Welded machine frame, stainless steel, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Footrests without dowel holes |

| Conveyor system with adjustable speed |

| Smooth PU carrying belt with cleaning lip on the outside to the product infeed |

| Infeed belt can be moved laterally for manual film setup |

| Stainless steel lateral guides above product infeed, manually adjustable |

| Film magazine, 1 roll with manually adjustable unwinding position |

| Manual set-up mode for film infeed |

| Crosswise sealing beam, permanent heated, pneumatically operated, non-stick coated |

| Adjustment unit for crosswise sealing beam, manual positioning in height and width |

| Transverse sealing station can be pulled out laterally |

| Cutting welding system for longitudinal sealing, permanently heated, pneumatically operated |

| Protection hood for lenghwise sealing aggregate |

| Venting of the package via lance according to injector principle |

| Winding roll for film residues, driven |

| Smooth PU carrying belt with cleaning lip on the outside to the product infeed |

| Electric socket, (SchuKo) 240V, 16A (or customer-specific) |

| Signal lamp - red light / green light |

| Signal horn |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Comfort-operating panel, rotatable with support arm system |

| Controls + touchpanel Omron |

| Automatic Stand-By in case of missing products |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

| Protection hoods made of perforated stainless steel panels |

| Additional signal lamp |

| Switch cabinet with air-conditioning |

| Frequency converter SEW |

| Frequency converter Allen Bradley |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

SW 40

The HARTMANN SW 40 L-sealing unit is ideal for full film wrapping of individual or grouped products. Variable pack sizes meet specific market requirements and product-related conditions.

The packs are created from a continuous film, which is folded and fed crosswise in two layers from a roll. Inside the machine, the products run in between the separated top and bottom film. A device could evacuate the package before final sealing. The film is sealed in transverse and longitudinal direction. The split-separated film overhang is collected on the roller provided for this purpose.

Good accessibility is provided by large door-openings and sliding or swivelling components. Adjustment devices are directly accessible and enable optimal handling.

| | |

|---|---|

| Dimensions: | Length: approx. 2350 mm, Width: approx. 1700 mm, Height: approx. 2250 mm |

| Weight: | approx. 1100 kg |

| Product dimensions: | Length: 250 - 600 mm, Width: 200 - 400 mm, Height: 60 - 170 mm |

| Capacity: | depending on products and packing scheme, theoretical max. 1200 packages/h (max. 20 packages/min) |

| Speed: | adjustable |

| Controller: | Siemens |

| Operating panel: | Touch panel |

| Control voltage: | 24 V, DC |

| Frequency controller: | SEW |

| Pneumatic system: | Festo |

| Power supply: | 400 Volt / 50 Hz |

| Power consuption: | approx. 4 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Packing material: | Product specific: Films on rolls, folded in double layers |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |