SLVS

Utilities Line Distribution System - SLVS

Pictures

Drawings

Standards

Standard specification

| |

|---|

| Footrests without dowel holes |

| Operating elements located in the machine panel or door of the switch box |

| Switch cabinet with fan+filter system - standard- |

| Hasp locking for cover panels |

| Signal lamp - red / green |

| Signal horn |

| Controls + touchpanel Omron |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Comfort-operating panel, rotatable with support arm system |

| Increased basement for switch cabinets, tubular stainless steel frame, h=200 mm |

| Sloping roof for the switch cabinet (30°), closed design |

| Switch cabinet with air-conditioning |

| Additional operating panel - build in a seperate control stand |

| Additional comfort-operating panel, with add-on rotatable with support arm system |

| Grid cable tray, open design |

| Closed squared cable tray (Brand Electrix Raceway) |

| Closed round cable tray (Brand Jacob) |

| Compressed air energy meter, data displayed on the touch screen |

| Switch cabinet with service interface FrontCom® with LAN and power socket |

| Additional signal lamp |

| Cable labeling with engraved signs, metal detectable |

| Potential-free contacts for circuit signaling with local components |

| Electric power consuption meter, electronic - data displayed on the touch screen and M-Bus capable |

| Three-phase energy meter Allen Bradley Power Monitor 1000 - For communication to the control or external connection |

| Remote service, VPN-Switch INSYS, (Master unit) |

| Connection to the central communication system. Customer specific depending on control system, amount of machines and amount of different data |

| RFID - Panel access authorization per chip, 10 pieces with up to 5 authorization levels |

| Voltage modulation, 3-phase |

| Transformer to modulate a neutral conductor |

| Isolating transformer |

| Overvoltage protection |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

FAQ

SLVS

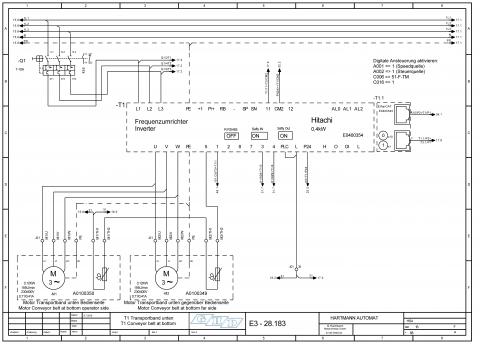

The Hartmann Line Distribution System contains all the components needed to control Hartmann conveying and handling systems, which are required for distributing, buffering or feeding products in an overall system. In addition to the electrical hardware with main switch, cable guides for power supply and control cables and switching devices also the corresponding control is included.

Technical specifications

| | |

|---|---|

| Dimensions: | Customer specific |

| Controller: | Omron |

| Operating panel: | Touchscreen |

| Frequency controller: | Customer specific |

| Pneumatic system: | Festo |

| Power supply: | 400 Volts , 50 cycles |

| Power consuption: | Customer specific |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Protection class: | IP 54 |