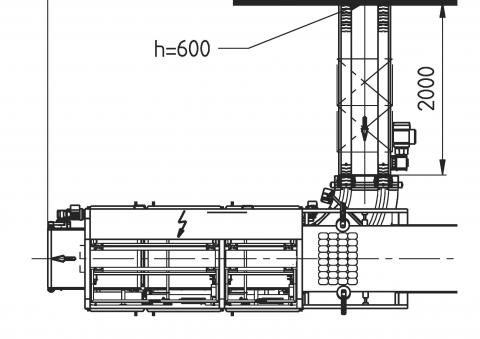

GBK 220

Automatic packaging machine for standing slices and whole bread.

- Automatic packaging and sealing in a machine

- Compact tight packaging

- For sliced and uncut breads or grouped products

| | |

| Product dimensions: | Length: 100 - 400 mm, Width: up to 260 mm, Height: 30 - 170 mm (other dimensions on request) |

| Capacity: | 1800 - 2700 packages /h |